Hydraulic cylinders are essential components in various industrial and mechanical applications. These devices convert hydraulic energy into linear motion, making them indispensable in construction, agriculture, manufacturing, and automotive industries. The two main types of hydraulic cylinders—single-acting and double-acting—offer distinct functionalities suited for different operational needs.

What Is a Single-Acting Hydraulic Cylinder?

A single-acting hydraulic cylinder operates using hydraulic pressure in only one direction. It relies on an external force, such as gravity or a spring, to return to its original position. This type of cylinder is commonly used in applications where controlled extension is required, but retraction can occur through external forces.

Key Features of Single-Acting Hydraulic Cylinders:

A single-acting hydraulic cylinder applies force in one direction using hydraulic pressure. When the pressure is released, it retracts through external forces like gravity or a built-in spring. This design makes it a cost-effective and low-maintenance solution for many applications. Due to its simple construction, it is lightweight and compact, making it suitable for portable equipment and systems where space is limited.

Common applications of single-acting cylinders include dump trucks, hydraulic jacks, lifting platforms, and presses. These cylinders are often chosen for tasks where precise retraction control is not necessary. Their minimal components also reduce maintenance costs, making them a popular choice for industries requiring straightforward and reliable force application.

What Is a Double-Acting Hydraulic Cylinder?

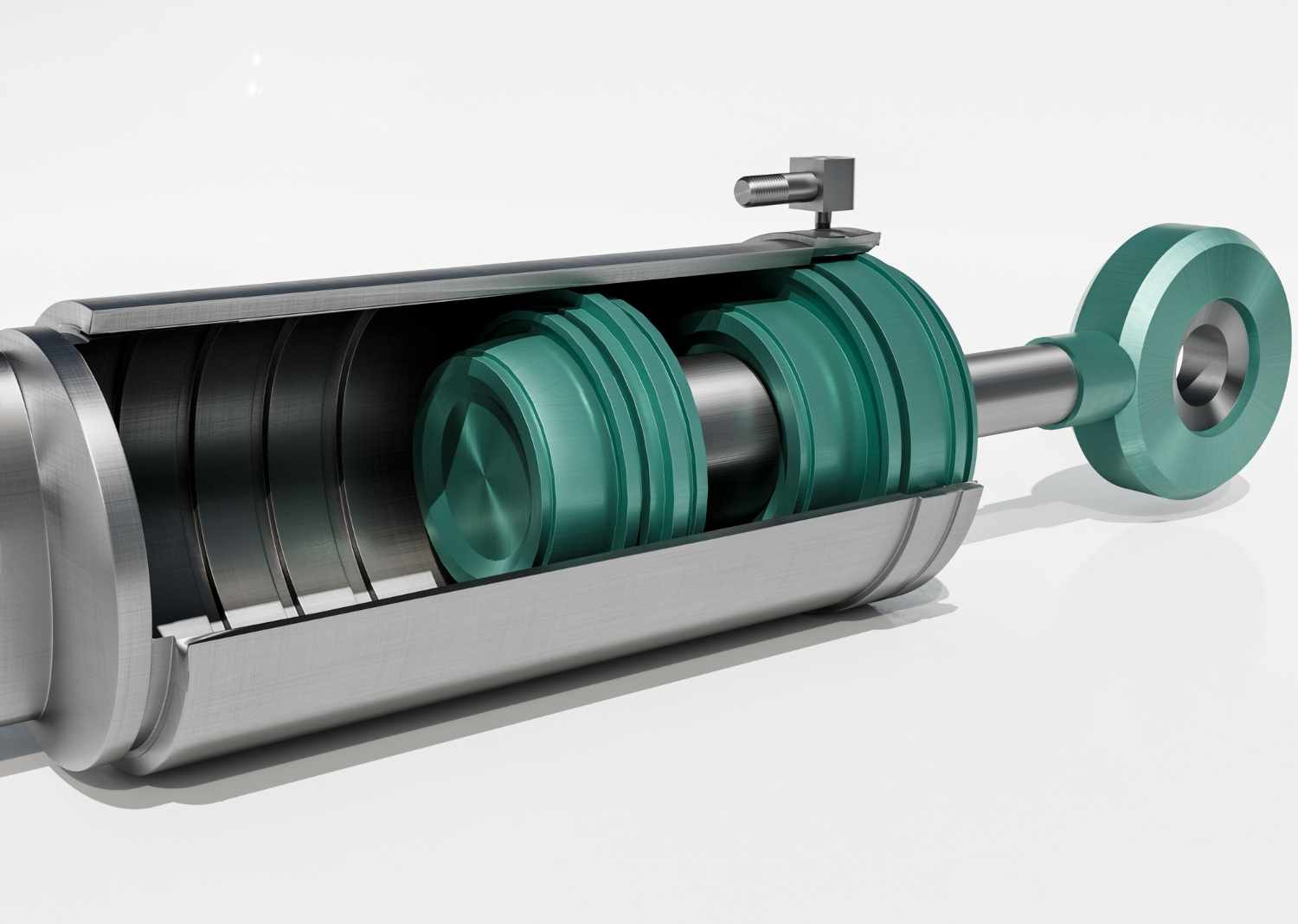

A double-acting hydraulic cylinder utilizes hydraulic pressure in both directions, allowing for controlled extension and retraction. Unlike single-acting cylinders, which rely on external forces for retraction, double-acting cylinders provide full operational control. This feature makes them ideal for applications that require precise movement and force in both directions.

Key Features of Double-Acting Hydraulic Cylinders:

Double-acting cylinders ensure smooth, controlled movement by applying hydraulic pressure on both sides of the piston. This allows for better force distribution, improved efficiency, and greater reliability in demanding applications. These cylinders offer enhanced precision, making them ideal for automation systems, industrial machinery, and heavy equipment.

Their robust design enables them to handle complex tasks, such as in excavators, forklifts, and hydraulic presses. Industries that require repetitive and controlled motion, such as manufacturing and construction, often prefer double-acting cylinders due to their versatility and superior performance.

Choosing the Right Hydraulic Cylinder for Your Needs

Load Requirements

The type of hydraulic cylinder you need depends on the force required for the task. Single-acting cylinders are best for applications with light to moderate loads where retraction can occur naturally. On the other hand, double-acting cylinders are essential for handling heavy loads where precise control over movement is required.

Motion Control

If your application requires only pushing or lifting forces without strict retraction control, a single-acting cylinder will suffice. However, if you need accurate bidirectional motion, a double-acting cylinder is the best choice. This is particularly important in industries where precision and efficiency are crucial.

Cost Considerations

Budget plays a significant role in selecting the right hydraulic cylinder. Single-acting cylinders are generally more affordable due to their simpler design. They require fewer components, which translates to lower maintenance costs. Double-acting cylinders, while more expensive, provide greater control and efficiency, making them a valuable investment for heavy-duty applications.

Environmental Factors

The operating environment also influences the choice of hydraulic cylinder. Single-acting cylinders are often used in outdoor applications where gravity or external forces assist in retraction. Double-acting cylinders, however, are better suited for controlled environments where precise movement is necessary. In industries like aerospace, robotics, and material handling, double-acting cylinders provide the consistency and reliability needed for high-performance operations.

Conclusion

Both single-acting and double-acting hydraulic cylinders have their advantages and are designed for different applications. Single-acting cylinders are best for simple, cost-effective operations where natural retraction is sufficient. Double-acting cylinders, on the other hand, provide superior control, making them ideal for complex and high-precision tasks. Understanding your operational requirements will help you make the right choice for your specific needs.

Write a comment ...