In the world of hydraulic and pneumatic systems, directional control valves play a key role in ensuring machines perform their tasks smoothly, efficiently, and with precision. Whether you are dealing with manufacturing equipment, construction machinery, or automated systems, directional control valves make sure that the movement of fluids is controlled accurately, helping to achieve the desired motion at the right time.

In this blog post, we’ll explain how directional control valves work, how they help achieve accurate and timed movements, their advantages, and why the market for directional control valves in India is growing steadily.

What Are Directional Control Valves?

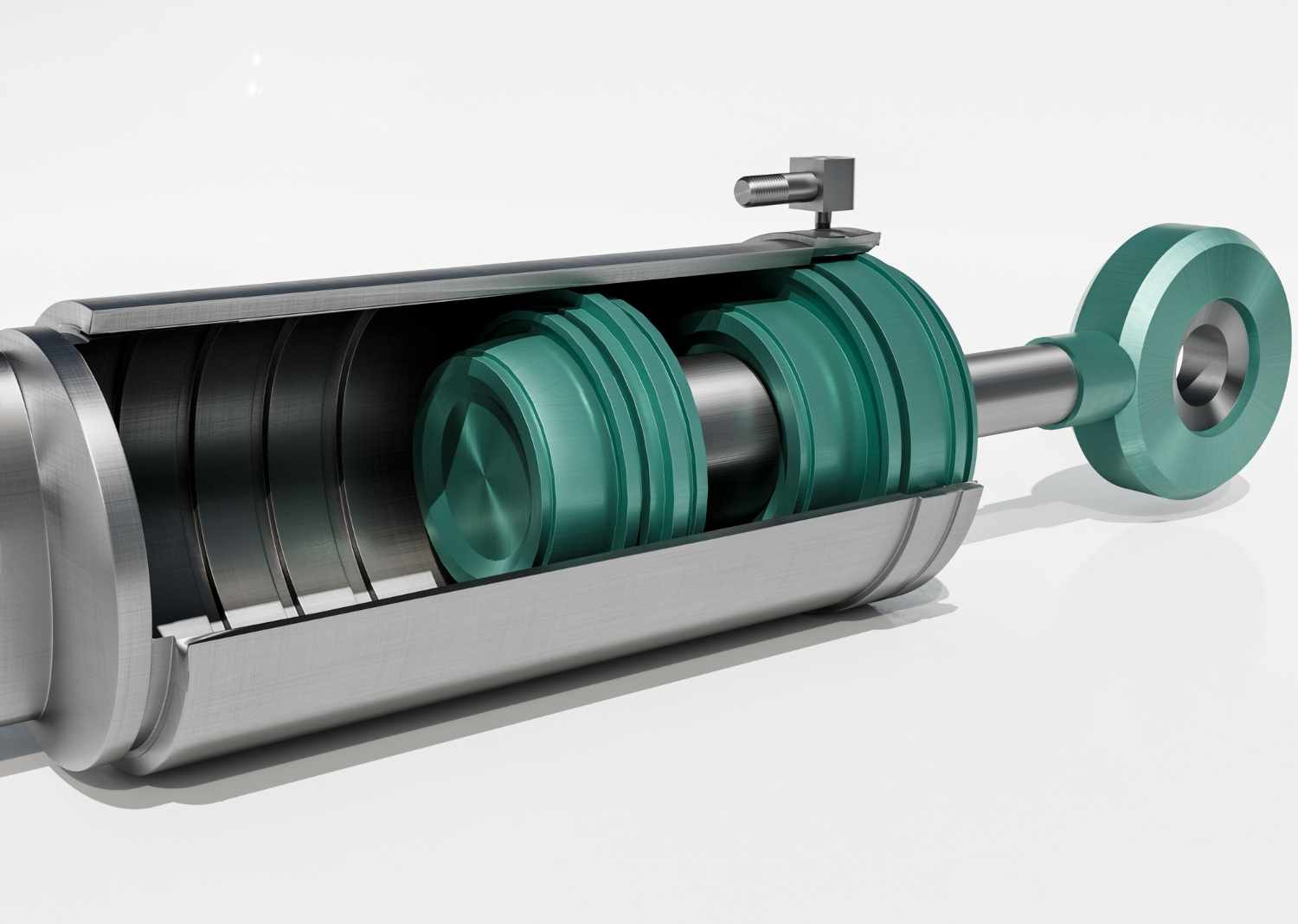

To put it simply, directional control valves are devices that manage the direction of fluid flow within a hydraulic or pneumatic system. They determine where the fluid (usually oil or compressed air) goes, controlling the movement of actuators like hydraulic cylinders or motors.

These valves consist of several ports and positions. The ports allow fluid to enter and exit the valve, while the valve’s positions control which ports are connected at any given moment. For example, a common 4/3-way directional valve has four ports and three possible positions, allowing for various combinations of fluid flow to control machine movements.

Without directional control valves, it would be extremely difficult to manage the motion, speed, and sequence of machinery in industrial systems.

How Do Directional Control Valves Work?

Directional control valves operate by opening and closing internal passages, directing fluid to different parts of the system. They can be operated in various ways, depending on the application:

Manual operation: Using levers, handles, or push-buttons.

Mechanical operation: Using cams or rollers.

Electrical operation: Using solenoids and coils.

Pneumatic or hydraulic pilot operation: Using pressure signals.

By switching between different positions, directional control valves can control when and where fluid flows, enabling machines to perform precise tasks.

How They Help Achieve Accurate and Timed Movements

Directional control valves are crucial in systems that require exact timing and controlled motion. Here’s how they contribute to accurate and timed movements:

1. Precise Control of Position

Directional control valves allow operators to position actuators with great accuracy. For instance, in a hydraulic press, the valve ensures that the cylinder moves down at just the right time and stops at the correct point, delivering consistent and repeatable performance.

2. Speed Regulation

While directional control valves primarily control the flow path, when combined with flow control devices, they can also help manage the speed of actuators. This prevents sudden or jerky movements, ensuring smooth operation.

3. Synchronization of Multiple Components

In complex systems with multiple actuators, synchronization is critical. Directional control valves help coordinate the movements of cylinders, motors, and other components, ensuring they work in harmony. This is especially important in automated production lines, packaging machines, and multi-stage processes.

4. Repeatability and Consistency

Industrial processes often require repeated operations, sometimes thousands of times a day. Directional control valves ensure each cycle is performed with the same timing and precision, reducing errors and improving product quality.

5. Enhanced Safety

By controlling the exact timing and sequence of fluid flow, directional control valves help prevent accidental or dangerous movements. Many systems also incorporate emergency or fail-safe positions within the valve design, adding an extra layer of protection for both operators and equipment.

Key Benefits of Directional Control Valves

The use of directional control valves brings several important advantages:

Improved system efficiency

Enhanced control over machine operations

Reduced energy consumption

Increased equipment lifespan

Lower maintenance and downtime

Better product quality through precise operations

These benefits make directional control valves indispensable in modern hydraulic and pneumatic systems.

Where Are Directional Control Valves Used?

Directional control valves are used across a wide range of industries and applications, including:

Manufacturing and automation: Robots, assembly lines, material handling equipment.

Construction equipment: Excavators, cranes, loaders, and bulldozers.

Agricultural machinery: Tractors, harvesters, and irrigation systems.

Automotive systems: Brakes, power steering, transmission systems.

Aerospace and defense: Landing gear systems, flight control systems.

In all these applications, directional control valves ensure that movements are carried out efficiently, accurately, and safely.

Why the Demand for Directional Control Valves in India is Growing

The demand for directional control valves in India has been growing steadily, and there are several reasons behind this trend:

1. Industrial Automation

Indian manufacturers are increasingly adopting automation to stay competitive in global markets. Automated systems require precise control, and directional control valves are a key component in achieving this.

2. Infrastructure Development

India’s infrastructure sector is booming, with major projects in roads, railways, airports, and ports. Construction machinery equipped with advanced hydraulic systems relies heavily on directional control valves.

3. Agricultural Modernization

India’s agricultural sector is embracing modern machinery to improve productivity. Tractors, harvesters, and other agricultural equipment use directional control valves to perform tasks efficiently.

4. Local Manufacturing Growth

With the government’s Make in India initiative, there’s been a significant push to boost local manufacturing of hydraulic components, including directional control valves. This has led to better availability, competitive pricing, and increased adoption across industries.

Choosing the Right Directional Control Valve

When selecting directional control valves for your system, it’s important to consider:

System requirements: Understand your pressure, flow rate, and temperature needs.

Valve type: Choose between spool, poppet, or rotary valves based on your application.

Actuation method: Decide between manual, electric, pneumatic, or hydraulic actuation.

Compatibility: Ensure the valve matches your existing system components.

Supplier reputation: Work with trusted manufacturers or distributors, especially when sourcing directional control valves in India, to ensure quality and reliability.

Final Thoughts

Directional control valves are the unsung heroes of hydraulic and pneumatic systems. They ensure that every motion — whether it’s lifting a load, extending a cylinder, or rotating a motor — happens precisely when and how it should. Without them, achieving accurate, timed, and synchronized movements would be nearly impossible.

As industries in India continue to grow and modernize, the importance of directional control valves in India will only increase. Understanding how these valves work and selecting the right type for your application can make a significant difference in system performance, safety, and efficiency.

If you are looking to improve your operations, now is a great time to explore how directional control valves can help you achieve greater precision and reliability.

Write a comment ...