When it comes to industrial equipment, businesses are always on the lookout for reliability, durability, and performance. Every piece of machinery needs to prove its worth — not just in the short run but over years of operation. That's exactly where piston pumps come into the picture. If you're working in sectors like manufacturing, oil & gas, agriculture, or chemical processing, you've likely come across these powerful little workhorses.

But what makes piston pumps stand out? Why are they considered a long-term investment in the industrial world? Let's dive in and understand what makes them worth every penny.

What Is a Piston Pump, Anyway?

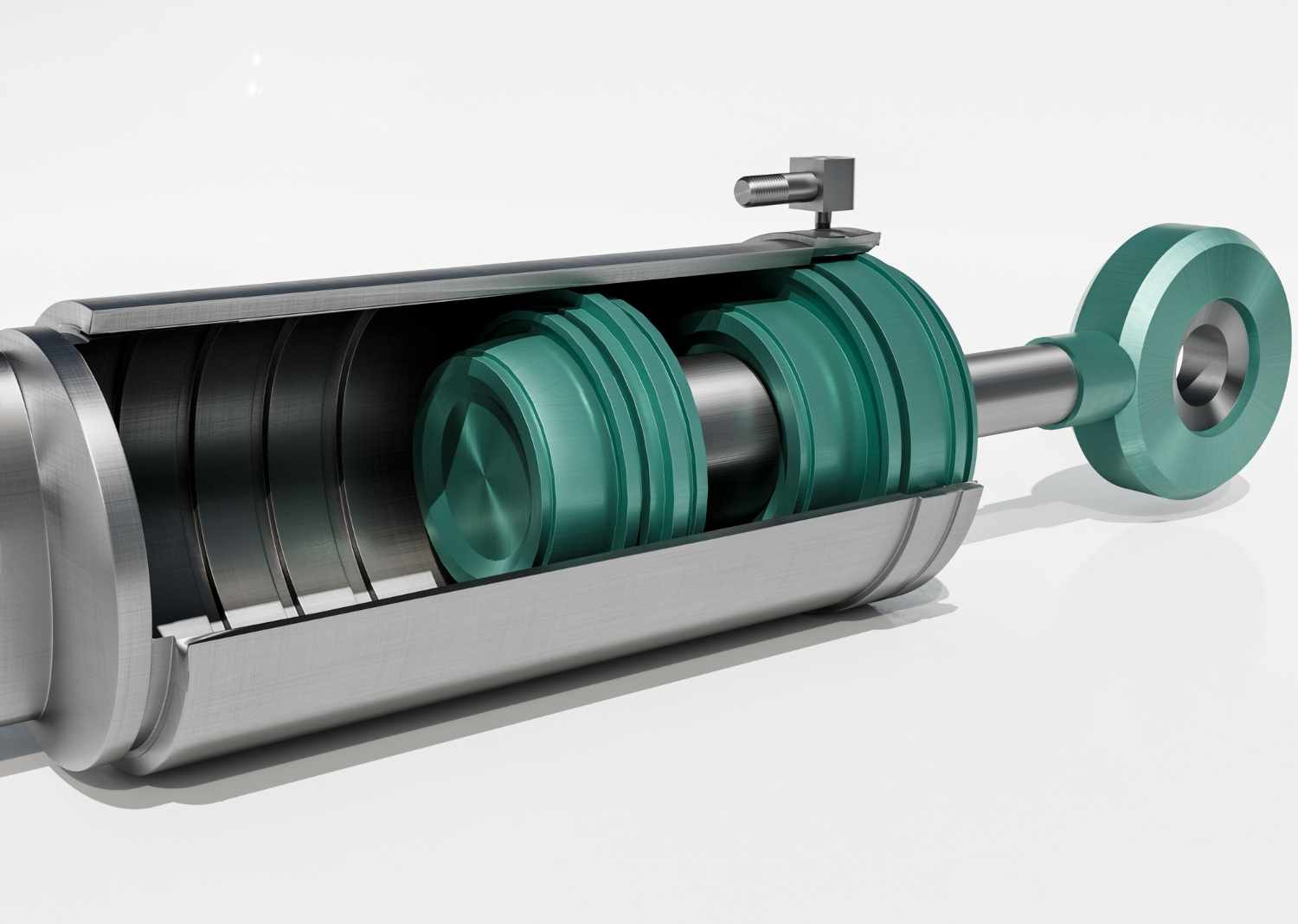

Before we talk about its long-term value, let's break it down. A piston pump is a type of positive displacement pump, meaning it moves fluids by trapping a fixed amount and forcing it into the discharge pipe. It uses a piston, plunger, or diaphragm to move the fluid. The real magic lies in the reciprocating motion of the piston, which creates high-pressure flow with precision.

There are mainly two types of piston pumps:

Axial piston pumps

Radial piston pumps

Each has its place depending on the application, but both are known for efficiency, control, and power.

Built to Handle Pressure (Literally!)

One of the top reasons piston pumps are favored in industry is their ability to handle high pressure without compromising flow rate. Where other pumps might struggle or wear out, piston pumps shine.

Imagine you're running a factory that needs a consistent and powerful water jet for cleaning equipment. A piston pump can maintain that strong, steady flow all day long. This is especially crucial in hydraulic systems, pressure washing, or injection systems.

Over time, that consistency leads to fewer breakdowns, better performance, and less downtime — all critical factors for any business.

Longevity Through Durability

Industrial settings aren't always kind. There's heat, pressure, dust, and wear from nonstop operation. So, durability isn't just a luxury — it's a necessity.

Piston pumps are built with this in mind. They typically feature:

Robust materials like stainless steel or cast iron

Replaceable parts like seals and valves

Tight tolerances for less internal leakage

When maintained properly, piston pumps can run for decades — not just years. In industries where capital equipment investments are significant, this kind of lifespan means better ROI (Return on Investment).

High Efficiency = Lower Operating Costs

Efficiency matters, especially when you're running machines all day long. Piston pumps operate with high volumetric efficiency, meaning they pump more liquid with less energy waste. This translates to:

Lower electricity consumption

Reduced heat generation

Minimal fluid loss

Over the life of the pump, these savings really add up. Companies not only save on energy bills but also avoid the costs associated with frequent repairs or replacements.

Versatility That Adapts With You

Industries evolve, and so do their needs. One of the great things about piston pumps is their versatility. They're suitable for a wide range of fluids — clean water, oil, chemicals, or even slurry. Whether you're pumping thin solvents or thick syrups, there's a piston pump for the job.

They're also adaptable to:

Varying temperatures

Changing pressures

Corrosive or abrasive substances

So, if your business expands or changes its process, chances are your piston pump can adapt right along with it. That adaptability is part of what makes them a smart long-term choice.

Low Maintenance, High Returns

Let's be honest — no one wants a machine that constantly needs attention. Thankfully, piston pumps score well in the low-maintenance department.

With periodic servicing, such as:

Replacing seals

Cleaning valves

Lubricating components

you can keep your piston pump running smoothly for years. Many modern models even come with self-lubricating components and wear-resistant coatings, further reducing maintenance efforts.

Fewer breakdowns mean fewer interruptions — and in an industry where time equals money, that's a huge advantage.

Precision Control in Industrial Applications

Another reason piston pumps are seen as long-term assets is their precise flow control. This is especially valuable in applications like:

Chemical dosing

Paint spraying

High-pressure cleaning

Fuel injection

Even when operating under high pressure, piston pumps deliver a stable and accurate flow rate, which means:

Less product wastage

Better process control

Higher-quality output

For industries that rely on accuracy, this feature alone makes piston pumps a worthwhile investment.

Real-World Industrial Applications

Let's put it into perspective. Here are just a few industries where piston pumps are not just useful — they're essential:

Oil & Gas: For transporting oil or injecting chemicals into wells

Food & Beverage: Used in processes like syrup transfer, bottle cleaning, or high-pressure homogenization

Pharmaceutical: Precision chemical dosing

Construction: Concrete pumping, water jet cutting

Agriculture: Irrigation systems and crop spraying

In all these sectors, equipment reliability can make or break operations. Piston pumps help businesses stay productive, competitive, and profitable.

Environmentally Friendly Operation

Sustainability is a growing priority in all industries. Because piston pumps are so efficient, they naturally contribute to energy conservation and lower emissions. Additionally, their long lifespan means less waste from equipment replacement.

Some newer models are also designed with eco-friendly materials and reduced noise output, making them more suitable for greener, more sustainable operations.

Final Thoughts: A Smart Investment That Pays Off

When you think about what you want from your industrial equipment, the list is simple: performance, reliability, longevity, and value.

Piston pumps deliver on all counts.

They work in tough environments. They handle high pressure with ease. They offer precise control, require minimal upkeep, and adapt to a wide range of applications. And most importantly — they last.

Sure, the initial investment might be higher than other types of pumps. But over time, the lower operating costs, reduced downtime, and unmatched durability make piston pumps one of the most cost-effective choices in the industry.

So, if you're planning for the future and want a solution that grows with your business, a piston pump isn't just a tool — it's a long-term partner.

Write a comment ...