When it comes to precision engineering, every component must perform with accuracy, reliability, and efficiency. Whether it’s robotics, aerospace, automotive, or industrial automation, engineers look for one critical component to ensure controlled motion and power transmission — planetary gear systems.

You might be wondering: Why are planetary gear systems preferred over other gearbox designs? The answer lies in their unique structure, compact size, high torque output, and long-lasting performance. Let’s dive into the reasons planetary gearboxes are the go-to choice in precision engineering projects worldwide.

What Is a Planetary Gearbox?

Before we explore its advantages, it’s essential to understand what a planetary gearbox is.

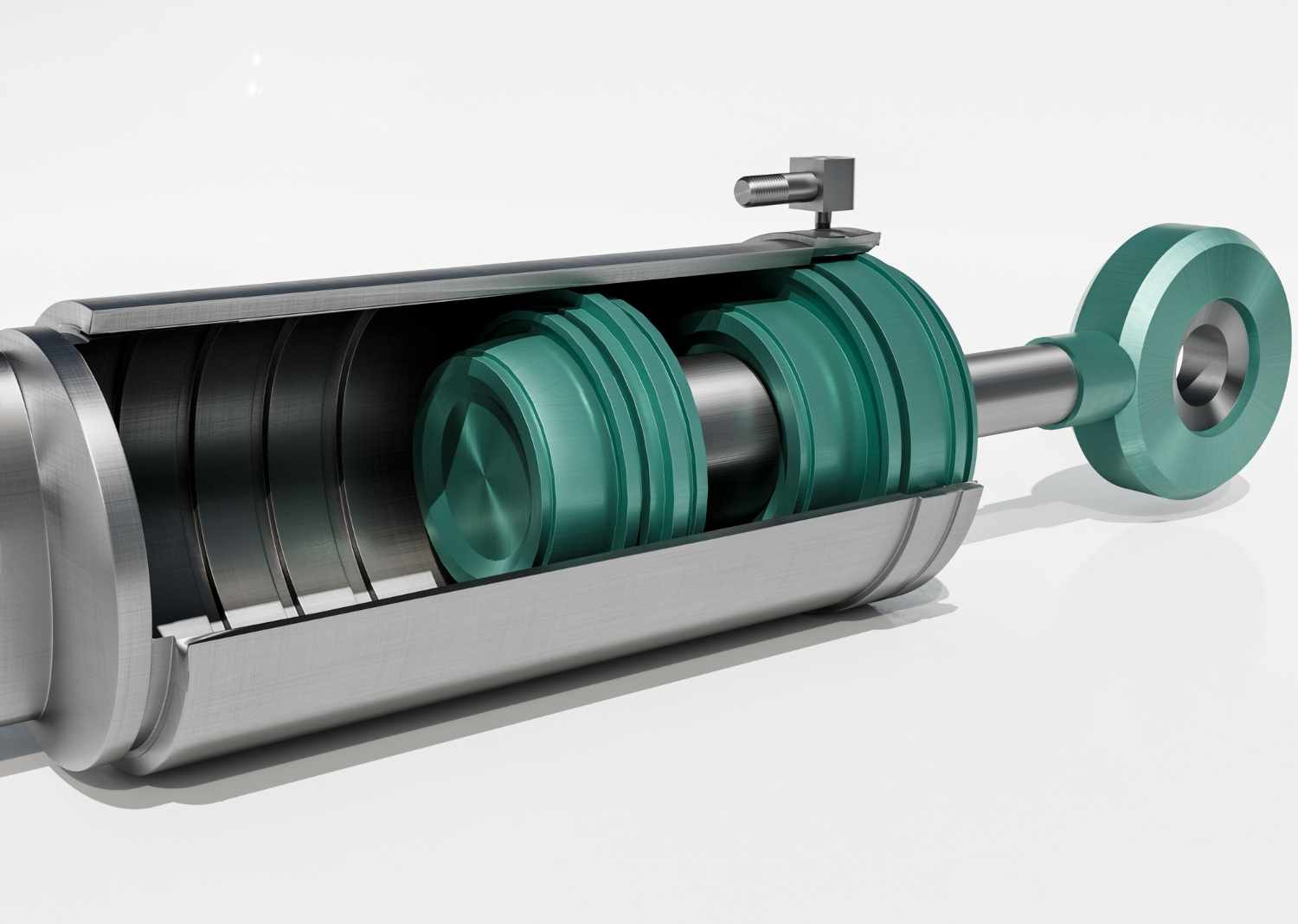

A planetary gearbox — also known as an epicyclic gearbox — is a type of gear system that consists of:

A central sun gear

Multiple planet gears rotating around the sun gear

An outer ring gear (with internal teeth) that meshes with the planet gears

A carrier that holds the planet gears in place

This design evenly distributes the load across multiple gears, resulting in superior torque transmission, compact design, and high efficiency.

Key Reasons Why Planetary Gear Systems Lead in Precision Engineering

1. Compact Design with High Power Density

In many precision engineering applications, space is limited, but power demand is high. This is where the planetary gearbox shines. Due to its compact nature, it delivers high torque output in a smaller footprint compared to traditional gear systems.

This feature is particularly valuable in robotic arms, CNC machinery, and aerospace devices where every millimetre counts.

2. Exceptional Load Distribution

Thanks to the multiple planet gears sharing the load, planetary gearboxes experience less wear and tear. The load is spread evenly, enhancing durability and reducing maintenance over time.

This makes planetary systems ideal for applications that demand long service life and continuous performance without failure — like industrial automation and heavy-duty machinery.

3. High Torque Transmission

One of the standout benefits of a planetary gearbox is its ability to transmit high torque in a small, efficient design. Whether it’s lifting a robotic limb or rotating a satellite dish, the high torque density allows smooth and powerful motion without the bulk of a larger gear system.

This is a key reason engineers choose planetary gear systems in performance-critical equipment.

4. High Efficiency with Minimal Energy Loss

Planetary gearboxes typically offer efficiencies of 95% or higher. This means less energy is lost in the gear transfer process, resulting in better system performance and reduced power consumption.

For applications where energy efficiency matters — such as electric vehicles or renewable energy systems — this level of performance is crucial.

5. Versatility in Gear Ratios

A planetary gearbox provides multiple gear ratio options in a compact design. Whether you need speed reduction or torque multiplication, these systems can be customized for various output needs without redesigning the entire drive system.

This versatility is perfect for engineers working across different industries, from medical devices to material handling systems.

Common Applications of Planetary Gearboxes

Thanks to their reliability and precision, planetary gear systems are used in a wide range of industries. Here are just a few examples:

Robotics: For precise movement control in joints and limbs

Automotive: In automatic transmissions and hybrid drivetrains

Aerospace: For lightweight, high-torque solutions in aircraft mechanisms

Medical Equipment: For reliable, noise-free motion in surgical tools and diagnostic machines

Industrial Automation: In conveyor systems, machine tools, and actuators

Wherever high precision and dependable performance are needed, a planetary gearbox is likely playing a silent but vital role.

Choosing the Right Planetary Gearbox

When selecting a planetary gear system for your project, consider the following:

Load capacity and torque requirements

Desired speed ratio

Mounting configuration

Operating environment (temperature, humidity, vibration)

Lubrication needs and maintenance schedule

Consulting with a trusted gearbox manufacturer or distributor will help ensure you get the best configuration for your specific engineering needs.

The Future of Planetary Gear Systems

With advancements in materials, design, and lubrication, planetary gearboxes are becoming even more efficient, quieter, and longer-lasting. As automation and robotics continue to evolve, so will the demand for high-precision gear systems that can support more complex and compact machines.

In addition, sustainability is pushing the development of energy-efficient mechanical systems — and planetary gear systems fit perfectly into this new era of eco-conscious engineering.

Final Thoughts

Planetary gear systems have earned their spot as the first choice in precision engineering for good reason. Their unmatched combination of compact design, high torque, and efficient load distribution makes them ideal for demanding, high-performance applications across multiple industries.

If your next engineering project requires power, precision, and reliability, consider integrating a planetary gearbox into your design. It’s a small component that can make a big difference in your system’s performance and longevity.

Write a comment ...