If you’re in the world of fluid handling, manufacturing, or engineering, you’ve likely come across both piston pumps and centrifugal pumps. These two pump types serve the same basic purpose — moving fluids — but the way they get the job done is very different. Choosing the right pump depends on your application, the type of fluid you’re working with, and how much control and pressure you need.

In this blog post, we’ll break down what makes a piston pump different from a centrifugal pump, including their working principles, typical uses, pros and cons, and key technical differences. Whether you’re selecting equipment for a new system or just curious about how things work, this guide has you covered.

What Is a Piston Pump?

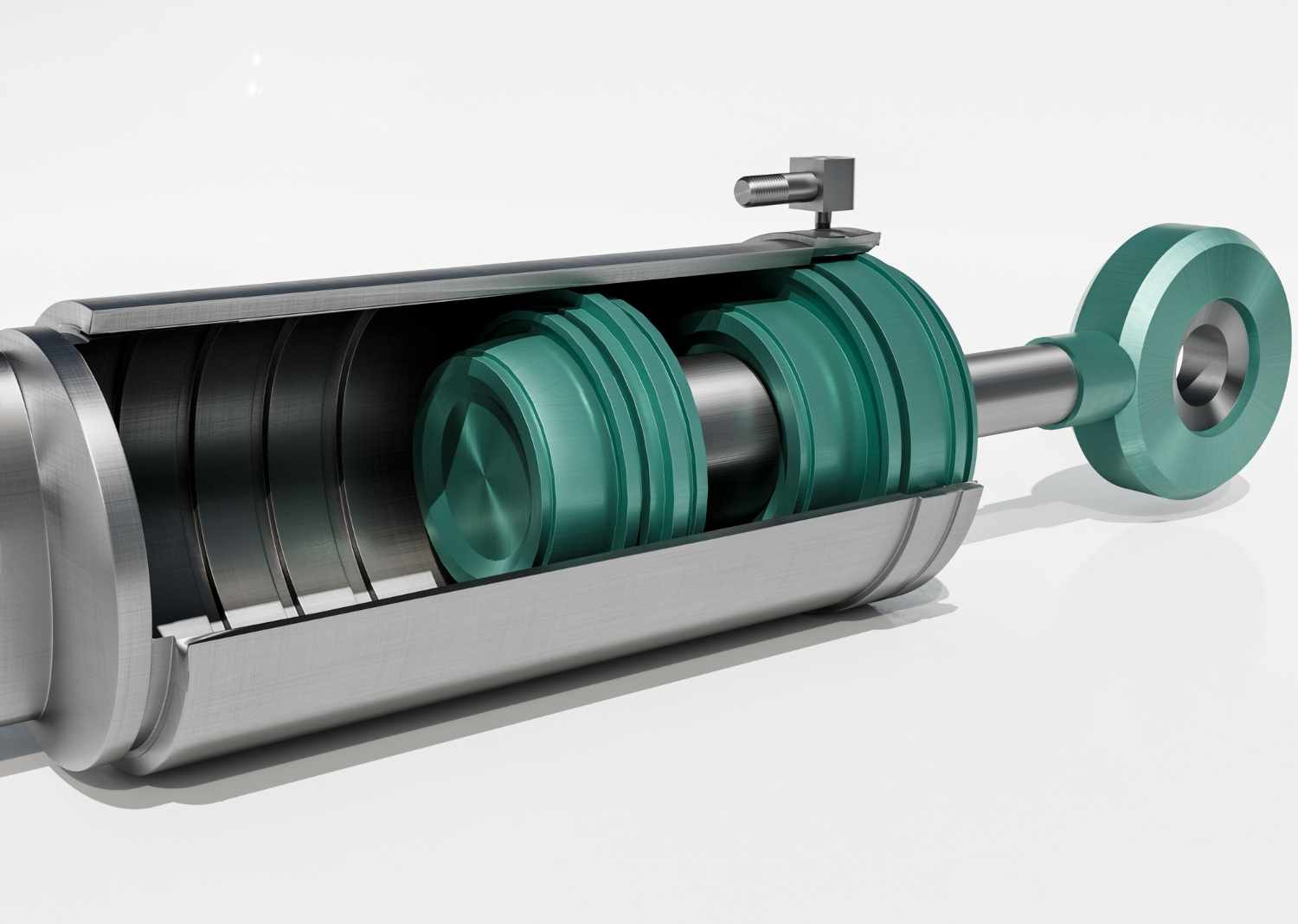

A piston pump is a type of positive displacement pump. It moves fluids by using a piston inside a cylinder. As the piston moves back and forth, it creates suction and pressure that pulls fluid in and pushes it out.

This type of pump is widely used in high-pressure applications like hydraulic systems, water jet cutting, and industrial cleaning because it can generate a strong and steady flow.

What Is a Centrifugal Pump?

A centrifugal pump, on the other hand, is a dynamic pump. It uses a rotating impeller to transfer energy to the fluid. When the impeller spins, it creates centrifugal force, which moves the fluid outward and into the pump outlet.

Centrifugal pumps are commonly used in applications where large volumes of fluid need to be moved at lower pressures — like in water supply systems, HVAC systems, and agricultural irrigation.

1. Working Principle

Piston Pump:

Works on positive displacement.

The piston moves in and out of a cylinder to physically displace the fluid.

Flow is created mechanically and is not dependent on pressure.

Centrifugal Pump:

Works on centrifugal force.

A spinning impeller creates velocity, converting kinetic energy into pressure to move the fluid.

Flow is influenced by system pressure and resistance.

Key Difference:

Piston pumps deliver a fixed volume with each stroke, while centrifugal pumps rely on rotational energy and system resistance to generate flow.

2. Flow Rate and Pressure Handling

Piston Pump:

Produces high pressure even at low flow rates.

Flow rate is consistent and controllable.

Centrifugal Pump:

Ideal for high flow rates, but at lower pressures.

Flow varies with changes in pressure and head.

Key Difference:

Piston pumps excel in high-pressure applications, while centrifugal pumps shine in high-flow, low-pressure tasks.

3. Efficiency

Piston Pump:

Highly efficient, especially in high-pressure environments.

Minimal energy loss due to consistent displacement.

Centrifugal Pump:

Efficiency depends on operating conditions.

Can be less efficient if running off-design or with viscous fluids.

Key Difference:

Piston pumps maintain high efficiency under pressure; centrifugal pumps may lose efficiency if not properly matched to the system.

4. Maintenance and Durability

Piston Pump:

More complex in design.

Contains moving parts like pistons, valves, and seals.

Requires regular maintenance due to wear and tear.

Centrifugal Pump:

Simpler design with fewer moving parts.

Low maintenance in clean fluid systems.

Impeller and seals are main wear items.

Key Difference:

Piston pumps are more durable under harsh conditions but need regular care. Centrifugal pumps are easier to maintain but best suited for clean, non-abrasive fluids.

5. Fluid Compatibility

Piston Pump:

Handles viscous, abrasive, or contaminated fluids well.

Suitable for fluids with varying consistencies.

Centrifugal Pump:

Best for clean, low-viscosity fluids like water or light chemicals.

Struggles with solids or thick liquids.

Key Difference:

Piston pumps are more versatile when dealing with tough fluids, while centrifugal pumps prefer clean and thin fluids.

6. Application Examples

Where Piston Pumps Are Used:

Hydraulic systems

High-pressure cleaning

Oil and gas industry

Chemical injection systems

Food and beverage processing

Where Centrifugal Pumps Are Used:

Water supply and treatment

Irrigation systems

HVAC circulation

Firefighting systems

Cooling towers

Key Insight:

Your choice depends largely on your pressure and fluid requirements. For high force and precise flow, go piston. For high-volume and low-pressure needs, go centrifugal.

7. Cost Consideration

Piston Pump:

Generally more expensive upfront due to complex design.

Long-term cost can increase due to maintenance.

Centrifugal Pump:

Lower initial cost.

Cost-effective in the long run if used in ideal conditions.

Key Difference:

Piston pumps are an investment for performance; centrifugal pumps are a budget-friendly option for simple jobs.

Conclusion: Which Pump Should You Choose?

Choosing between a piston pump and a centrifugal pump isn’t about which one is better — it’s about which one is right for your specific needs.

If you’re dealing with:

High pressures

Thick or dirty fluids

A need for precision

then a piston pump is your best bet.

If you’re handling:

Large volumes of clean water

Low-pressure systems

Cost-sensitive applications

then a centrifugal pump is likely the smarter choice.

Take the time to understand your system requirements, and you’ll end up with a pump that runs smoothly, efficiently, and reliably for years to come.

Write a comment ...