When it comes to industrial applications that require linear motion, hydraulic and pneumatic cylinders are two of the most common choices. Both systems have their unique advantages and limitations, making them suitable for specific uses. Understanding the differences between these two types of cylinders will help you determine which one is the best fit for your needs.

Understanding Hydraulic Cylinders

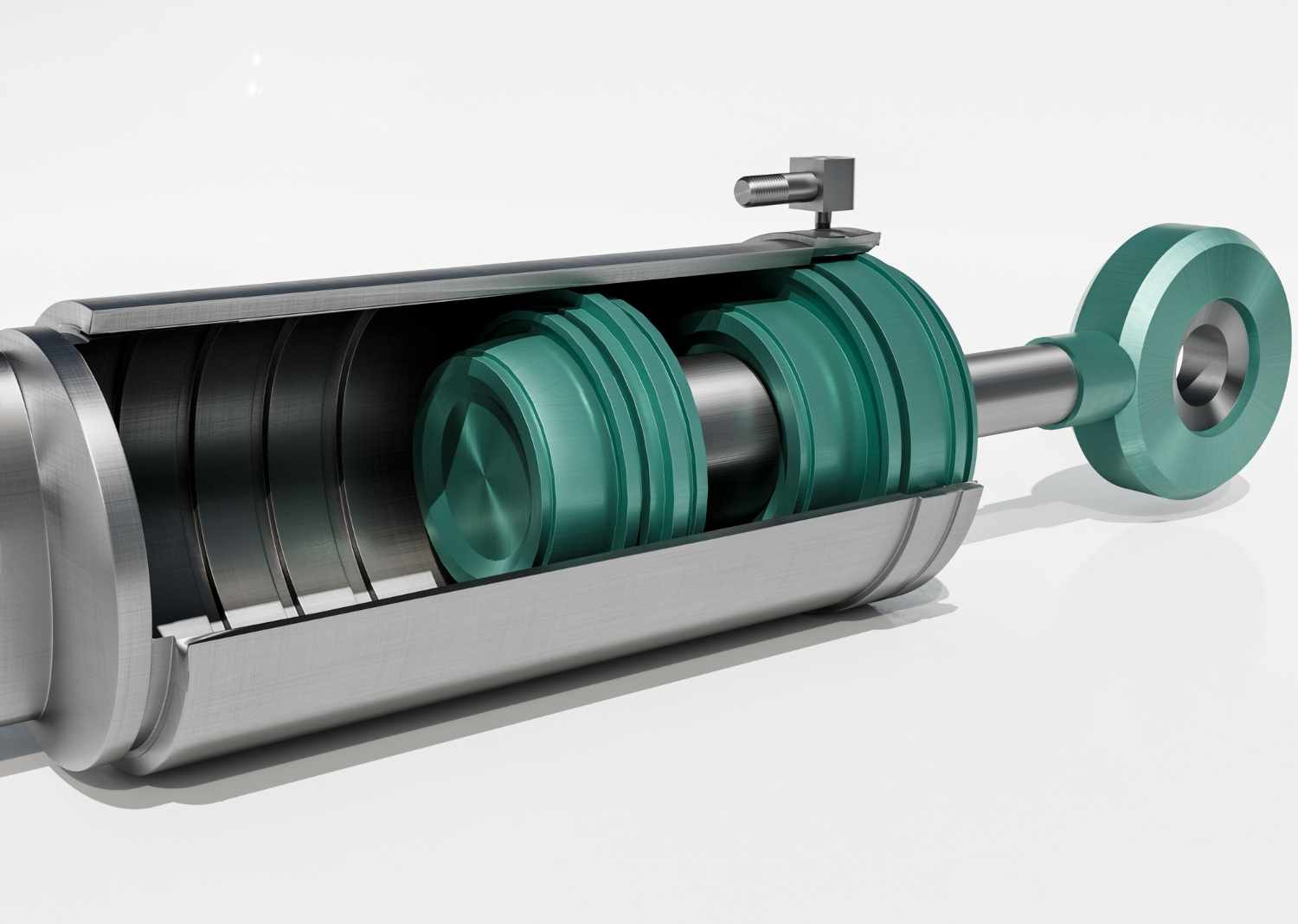

Hydraulic cylinders use liquid (typically hydraulic oil) to generate force. These systems are widely used in heavy-duty applications such as construction equipment, industrial machinery, and automotive systems.

Advantages of Hydraulic Cylinders

High Power Output – Hydraulic systems provide exceptional force, making them ideal for heavy lifting and high-load applications.

Precise Control – Hydraulic cylinders offer excellent speed and force control, allowing for smooth and accurate movements.

Durability and Longevity – These cylinders are built to withstand extreme pressures and harsh environments, ensuring a long operational life.

Continuous Load Handling – Unlike pneumatic systems, hydraulic cylinders can maintain force and pressure consistently over extended periods.

Disadvantages of Hydraulic Cylinders

Complex Maintenance – Hydraulic systems require regular maintenance due to potential fluid leaks, contamination, and pressure loss.

High Initial Cost – The installation of hydraulic systems is often more expensive due to the need for pumps, valves, and reservoirs.

Slow Response Time – Compared to pneumatic cylinders, hydraulic systems tend to have a slower response time due to fluid dynamics.

Understanding Pneumatic Cylinders

Pneumatic cylinders use compressed air to generate motion and force. They are commonly used in automation systems, manufacturing, food processing, and medical equipment.

Advantages of Pneumatic Cylinders

Fast Operation – Pneumatic cylinders have quick response times, making them suitable for high-speed operations.

Clean and Safe – Since they use air instead of oil, pneumatic systems are cleaner and more environmentally friendly, reducing contamination risks.

Lower Initial Cost – Pneumatic systems require fewer components, making them more affordable to install compared to hydraulic systems.

Low Maintenance – With fewer moving parts and no risk of fluid leaks, pneumatic cylinders require less maintenance.

Disadvantages of Pneumatic Cylinders

Limited Power Output – Pneumatic cylinders generate less force compared to hydraulic cylinders, making them unsuitable for heavy-duty applications.

Inefficiency in Large-Scale Operations – Compressing air consumes a lot of energy, which can lead to higher operational costs.

Inconsistent Pressure Maintenance – Unlike hydraulic systems, pneumatic cylinders struggle to maintain consistent pressure over time.

Choosing the Right Cylinder for Your Needs

When deciding between hydraulic and pneumatic cylinders, consider the following factors:

Load Requirements – If your application involves heavy loads, hydraulic cylinders are the better option. For lighter loads, pneumatic cylinders are sufficient.

Speed and Precision – Pneumatic cylinders excel in high-speed applications, while hydraulic cylinders offer superior precision and control.

Environmental Considerations – If you need a clean and contamination-free environment, pneumatic cylinders are the ideal choice.

Budget Constraints – While pneumatic systems have lower upfront costs, hydraulic systems may provide better long-term value due to their durability and strength.

Maintenance Requirements – Pneumatic systems require less maintenance, whereas hydraulic systems demand regular inspections to prevent fluid leaks and pressure drops.

Conclusion

Both hydraulic and pneumatic cylinders offer distinct advantages depending on your application. If you need high force, durability, and precision, hydraulic cylinders are the way to go. However, if you prioritize speed, affordability, and cleanliness, pneumatic cylinders might be the better choice.

Selecting the right system depends on your specific requirements, operational environment, and budget. Understanding these differences will help you make an informed decision and optimize your machinery’s efficiency.

Write a comment ...