When it comes to hydraulic systems, axial piston pumps are a popular choice due to their high performance and reliability. But one question that often comes up is: Are parallel shafts always better for axial piston pumps?

The answer isn't a straightforward yes or no. It depends on your specific application, performance requirements, and environmental conditions. In this blog, we'll break down what parallel shafts are, the advantages and drawbacks of using them, and how they compare to other shaft types—particularly in real-world use.

What Are Parallel Shafts in Axial Piston Pumps?

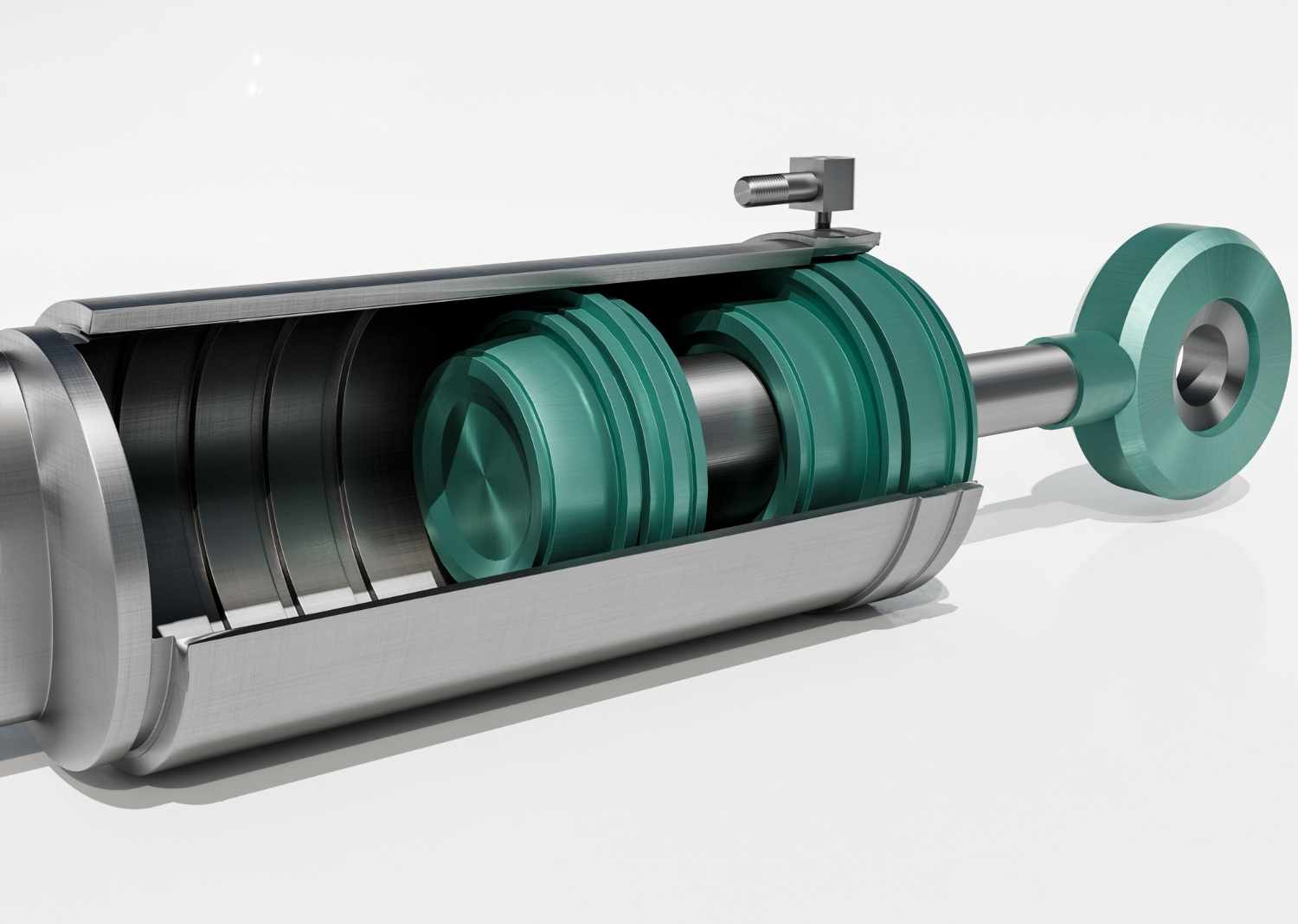

In axial piston pumps, the pistons move in a direction parallel to the drive shaft. When we talk about “parallel shafts,” we're referring to the shaft arrangement where the drive shaft runs in the same direction as the pistons.

This is typically seen in swash plate-type axial piston pumps, where the angle of the swash plate controls the piston stroke and, therefore, the fluid flow. This design allows for smooth and adjustable flow control, making it ideal for many applications.

Why Are Parallel Shafts Popular?

Parallel shaft pumps are widely used for several reasons:

1. Compact Design

One of the biggest advantages of parallel shaft designs is their compact size. They are easier to install in machines or vehicles with limited space. This makes them ideal for mobile equipment, such as construction and agricultural machinery.

2. Cost-Effective

Because the design and manufacturing process for parallel shaft pumps is relatively simple, they tend to be more affordable than other types, such as bent-axis pumps. If you're looking for a budget-friendly solution without compromising basic performance, this can be a good option.

3. Easier Maintenance

Parallel shaft axial piston pumps are usually easier to service. The straight alignment of internal components makes disassembly and inspection simpler. This can save you time and money when maintenance is required.

4. Smooth Performance at Moderate Pressures

These pumps run smoothly at low to medium pressures, providing steady fluid flow. They're great for applications that don't demand extreme power but still require consistent performance.

But Are They Always Better?

Despite the advantages, parallel shafts are not always the best choice. Like any mechanical system, there are trade-offs. Here are a few limitations to keep in mind:

1. Not Ideal for High Pressure

If your system needs to operate at very high pressures, parallel shaft designs might struggle. They tend to generate more internal friction and heat under high stress, which can reduce efficiency and lead to quicker wear.

2. Heat Build-Up

Since the pistons in a parallel shaft pump push directly against a swash plate, they can produce more heat during long or heavy-duty cycles. Without proper cooling, this heat build-up can affect performance and lifespan.

3. Increased Wear in Heavy-Duty Operations

The contact between the pistons and the swash plate may lead to more wear over time, especially if the pump is operating under heavy load or continuous duty. This means more frequent maintenance in tough industrial environments.

What About Bent-Axis Pumps?

To understand whether parallel shafts are better, it helps to know what they're being compared against. Bent-axis axial piston pumps use a different design where the piston block and shaft are placed at an angle.

This allows for greater mechanical efficiency at high pressures and improved cooling. However, bent-axis pumps are often larger, more complex, and more expensive.

So, if your application involves high pressure and continuous operation, a bent-axis design might be a better choice. On the other hand, if your system runs at moderate pressures and you want a compact, cost-effective solution, parallel shafts make more sense.

When Should You Use a Parallel Shaft Pump?

You should consider using an axial piston pump with a parallel shaft configuration if:

You have limited installation space.

Your system operates under moderate pressure.

You want easier access for maintenance and repairs.

You're working with a limited budget.

You need reliable performance in mobile or light industrial equipment.

Applications like tractors, forklifts, light construction vehicles, and some manufacturing systems often benefit from this type of pump.

When Should You Avoid Parallel Shaft Designs?

You may want to avoid parallel shafts in axial piston pumps if:

Your system runs at very high pressure or requires continuous operation.

You need better cooling and heat management.

Your application demands maximum energy efficiency.

You're working in a harsh industrial setting that accelerates wear and tear.

In such cases, a bent-axis design or another high-performance pump may be more appropriate, even if the cost is slightly higher.

Final Thoughts

So, are parallel shafts always better for axial piston pumps? The answer depends entirely on your needs.

They are better when you're looking for a compact, affordable, and easy-to-maintain pump that operates in low to medium-pressure systems. But they may not be the best choice for high-pressure, heavy-duty operations where efficiency and durability are critical.

Choosing the right axial piston pump means balancing cost, performance, space, and long-term reliability. Don't just pick a design based on popularity or assumptions—take the time to evaluate your system requirements.

Write a comment ...