In today's world of smart machines and industrial automation, proportional valves play a crucial role. These valves help control the flow, pressure, and direction of hydraulic or pneumatic fluid in a system. But what makes them truly smart and efficient is electronic control.

In this blog post, we'll explore the role of electronic control in proportional valves — how it works, why it's important, and the benefits it brings to modern industries.

What Are Proportional Valves?

Before diving into electronic control, let's first understand what proportional valves are.

A proportional valve is a type of control valve that adjusts flow or pressure in proportion to an electrical input signal. Unlike simple on/off valves, proportional valves allow precise and variable control. This makes them ideal for applications that require smooth motion and fine adjustments.

You'll often find them in industries like:

Manufacturing automation

Mobile machinery (like construction equipment)

Injection molding machines

Robotics

Aerospace systems

Why Electronic Control Matters

So, where does electronic control come into play?

Electronic control is what makes a proportional valve “intelligent.” Instead of manual operation or basic switches, an electronic controller receives input from sensors or PLCs (programmable logic controllers) and sends signals to the valve. These signals tell the valve how much to open or close.

This real-time communication enables:

Faster response times

More accurate control

Remote adjustments

Integration with other smart systems

In short, electronic control is the brain behind the proportional valve's movements.

How Electronic Control Works in Proportional Valves

Let's break down how electronic control operates in a proportional valve system.

1. Input Signal

The system sends an electrical signal (usually a voltage or current) to the valve. This signal could come from:

A joystick

A control panel

A sensor

A computer or PLC

This signal tells the valve what to do — for example, increase pressure or reduce flow.

2. Electronic Driver (Amplifier)

The input signal goes through an electronic driver, also called an amplifier. This device adjusts the signal and sends it to the valve's solenoid.

Think of it as a translator between the control system and the valve.

3. Solenoid Activation

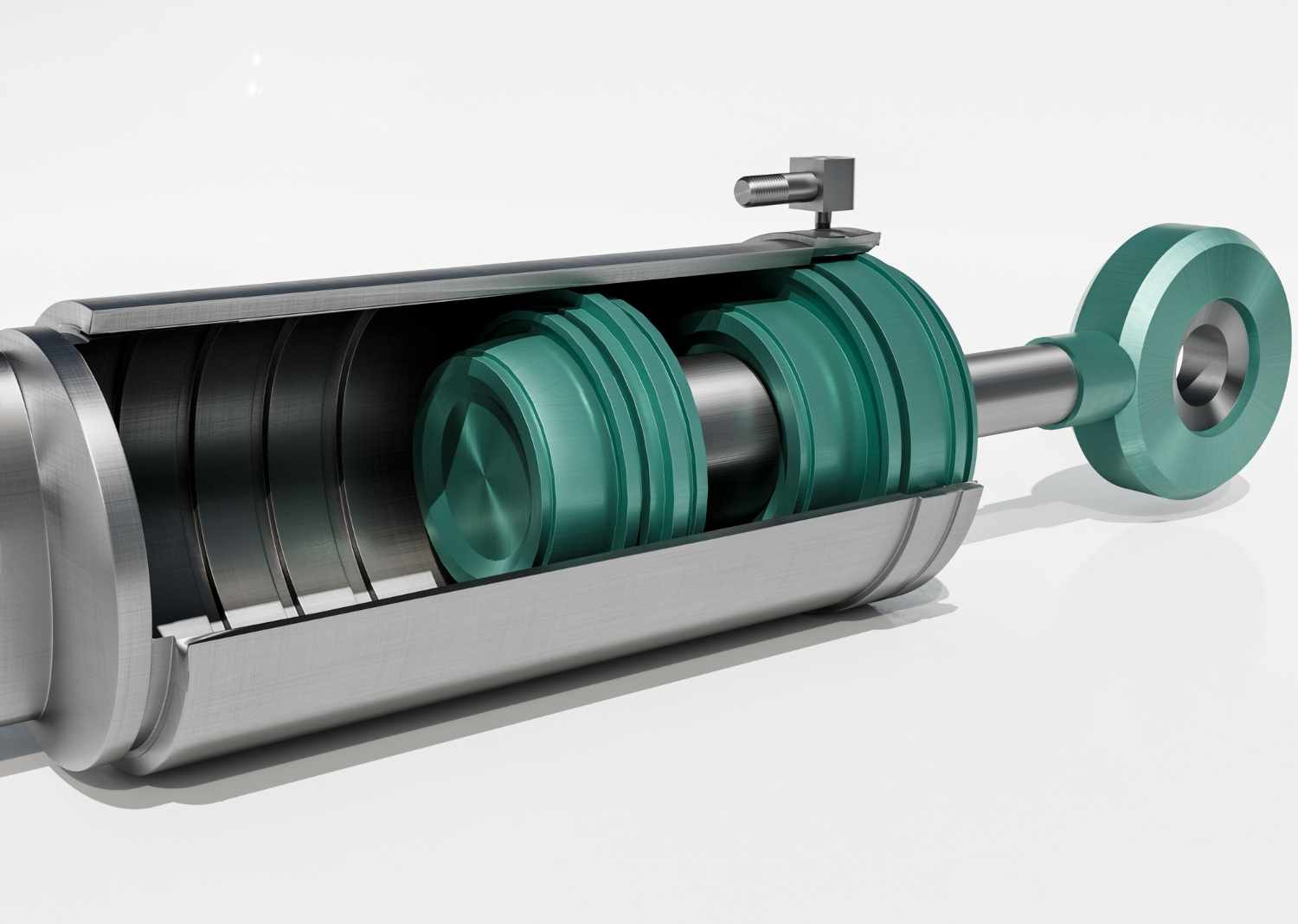

The solenoid is an electromagnet that moves a spool or poppet inside the valve. The more current it receives, the more it moves the internal mechanism. This movement controls how much fluid passes through the valve.

4. Feedback and Adjustment

Many modern systems include closed-loop control, where sensors monitor pressure or flow and send feedback to the controller. If something is off, the controller automatically adjusts the signal to the valve.

This loop ensures accuracy, consistency, and energy efficiency.

Benefits of Electronic Control in Proportional Valves

Using electronic control in proportional valves offers many advantages, especially in industrial settings. Let's take a closer look.

1. Precise Control

With electronic signals, you can fine-tune valve behavior to match exact system needs. This level of control is essential for processes that require high accuracy, such as injection molding or CNC machinery.

2. Faster Response Time

Electronic control systems react quickly to changes in input. This fast response is critical in applications like robotics, where every millisecond counts.

3. Energy Efficiency

By adjusting only as much as needed, proportional valves help reduce unnecessary fluid movement. This leads to lower energy use and cost savings.

4. Reduced Wear and Tear

Smooth control means less stress on mechanical components. Over time, this leads to fewer breakdowns and longer equipment life.

5. Easy Integration with Automation Systems

Electronic control makes it simple to integrate proportional valves into smart factories, IoT-enabled equipment, or automated production lines.

With a central controller or PLC, you can monitor and manage every valve in the system remotely.

Common Applications of Electronically Controlled Proportional Valves

Let's look at where these valves are commonly used:

Industrial Machinery

In factories, proportional valves are key for controlling motors, actuators, and cylinders. Electronic control ensures consistent movement and product quality.

Mobile Equipment

Modern excavators, cranes, and agricultural machines use electronically controlled valves for smooth operation and energy savings.

Medical Devices

Even in healthcare, precise fluid control is essential. Devices like dialysis machines and anesthesia systems rely on proportional valves for accuracy.

Automotive Manufacturing

In robotic welding and painting systems, proportional valves help manage pressure and flow with high precision.

Things to Consider When Choosing a Proportional Valve

If you're selecting a proportional valve for your system, here are a few things to keep in mind:

Signal Type: Ensure compatibility with your PLC or controller (voltage or current).

Valve Size and Flow Range: Pick the right size based on the fluid volume and pressure in your system.

Feedback Capabilities: For high-precision needs, choose a valve with position or pressure feedback.

Environment: Consider protection against moisture, dust, or extreme temperatures.

Brand Reputation: Always choose reliable manufacturers with proven track records.

The Future of Proportional Valves and Electronic Control

As automation and Industry 4.0 technologies grow, electronic control of proportional valves will become even more important. Expect to see:

More smart valves with built-in sensors and diagnostics

Enhanced communication with IoT platforms

Predictive maintenance using real-time data

AI-powered control algorithms for maximum efficiency

In short, we're just getting started with what's possible.

Final Thoughts

Proportional valves may seem like small components in large machines, but they play a huge role. And with electronic control, they become powerful tools for precision, efficiency, and smart automation.

Whether you're working in manufacturing, mobile hydraulics, or medical devices, understanding the role of electronic control in proportional valves can help you build better systems — and stay ahead in the world of modern engineering.

Write a comment ...