Hydraulic cylinders play a crucial role in the performance of heavy-duty machinery. Whether you're working in construction, agriculture, manufacturing, or material handling, choosing the right type of hydraulic cylinder can make a significant difference in reliability, longevity, and maintenance.

Two common types of hydraulic cylinders are tie-rod cylinders and welded cylinders. Each has its advantages and limitations, and understanding their differences is key to selecting the right one for your application. In this post, we'll break down the pros and cons of both tie-rod and welded hydraulic cylinders to help you make an informed decision.

What Are Tie-Rod Hydraulic Cylinders?

Tie-rod hydraulic cylinders are designed with high-strength steel rods that run the entire length of the cylinder body. These rods hold the end caps in place, ensuring structural integrity under pressure. Tie-rod cylinders are widely used in industrial machinery, thanks to their modular design and ease of maintenance.

Pros of Tie-Rod Hydraulic Cylinders

Easy Maintenance and Repairs

One of the most significant advantages of tie-rod cylinders is that they are easy to disassemble. The modular construction means that individual parts can be replaced without the need for welding or special tools, making them ideal for environments where downtime must be minimized.

Cost-Effective for Standard Applications

Tie-rod cylinders are often more affordable upfront, especially in standard sizes and specifications. This makes them a good option for general-purpose industrial applications where extreme customization isn't required.

Standardized Design

These cylinders typically follow NFPA (National Fluid Power Association) standards, allowing for easy interchangeability with other equipment or brands. This is helpful when replacing parts or upgrading existing systems.

Customizable Lengths

Because of their construction, tie-rod cylinders can be easily configured to various stroke lengths by simply adjusting the rod length.

Cons of Tie-Rod Hydraulic Cylinders

Bulkier Design

Tie-rod cylinders are usually larger in size compared to welded cylinders, which can be a limitation in space-constrained applications. Their exposed tie-rods also make them less compact and more vulnerable to damage in harsh environments.

Not Ideal for Mobile Equipment

Due to their size and weight, tie-rod cylinders are less common in mobile equipment like excavators or agricultural machines. The exposed rods can also corrode or break if subjected to dirt, debris, or chemicals.

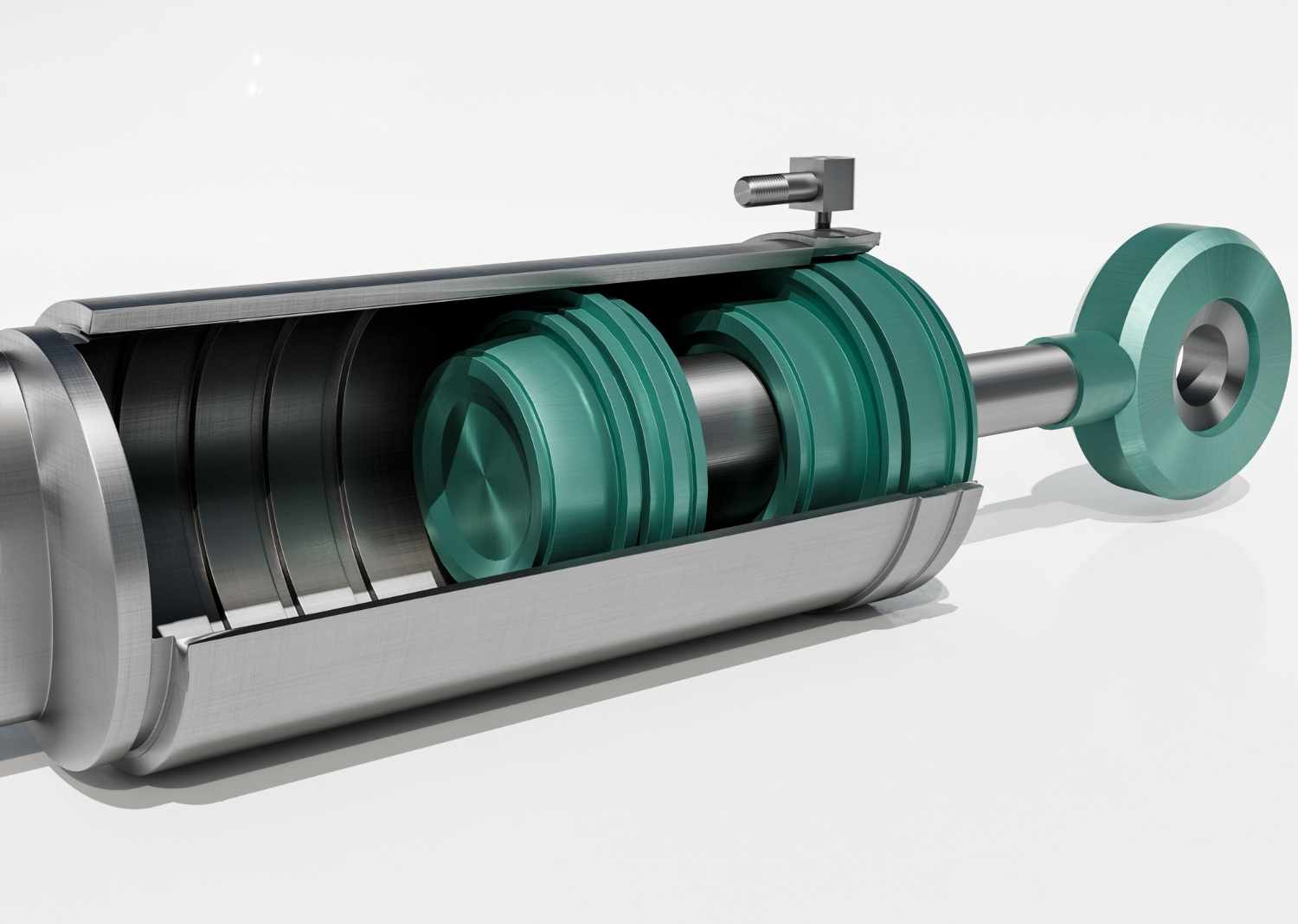

What Are Welded Hydraulic Cylinders?

Welded hydraulic cylinders have a more compact design. In these cylinders, the end caps are welded directly to the cylinder barrel. This eliminates the need for tie rods and creates a sealed, rigid structure. Welded cylinders are common in mobile and heavy-duty equipment, especially in construction and mining industries.

Pros of Welded Hydraulic Cylinders

Compact and Rugged Design

The welded construction allows these cylinders to be more compact, making them perfect for applications where space is limited. Their sealed design also makes them better suited for harsh environments—dust, mud, moisture, and chemicals have a harder time penetrating the cylinder body.

Higher Pressure Capability

Welded cylinders are typically built to withstand higher operating pressures, making them ideal for heavy-duty and high-performance applications such as excavators, cranes, and large agricultural machines.

Customization Options

Because they're often custom-built, welded cylinders offer more flexibility in design. Whether you need special mounting options, port locations, or stroke lengths, these cylinders can be tailored to fit.

Longer Service Life

With fewer external parts and no tie-rods that can loosen over time, welded cylinders are generally considered to have a longer service life when used correctly.

Cons of Welded Hydraulic Cylinders

More Difficult to Service

One of the primary drawbacks of welded cylinders is maintenance complexity. Since the ends are welded shut, repairs require cutting and re-welding, which is not ideal in field situations. You may also need specialized tools or return it to the manufacturer for servicing.

Higher Initial Cost

Welded cylinders can be more expensive upfront, especially if custom-built. However, this cost is often offset by their durability and extended lifespan in demanding environments.

Limited Standardization

Unlike tie-rod cylinders, welded cylinders are not always built to a universal standard, which can make replacements and upgrades more challenging. It also limits interchangeability between manufacturers.

Which One Should You Choose?

The decision between tie-rod and welded hydraulic cylinders depends on your specific needs, environment, and budget.

Choose Tie-Rod Cylinders If:

You need a cost-effective, easily serviceable option.

You operate in a clean, indoor environment (e.g., factories or production lines).

Your application involves moderate pressure requirements.

You value easy part replacement and fast repairs.

Choose Welded Cylinders If:

You need a compact, rugged solution for outdoor or mobile equipment.

Your application involves high pressure or continuous heavy-duty cycles.

You're looking for long-term performance with less frequent maintenance.

You're working in dirty, corrosive, or high-impact environments.

Final Thoughts

Both tie-rod and welded hydraulic cylinders have their place in modern machinery. Understanding their structural differences, strengths, and limitations is the key to choosing the right component for your hydraulic system.

If you're unsure which type suits your equipment best, consult with a hydraulic systems expert or manufacturer. A small decision today can save you significant time and cost down the road.

At the end of the day, it's not about which type is better overall—it's about which one is better for your application.

Write a comment ...